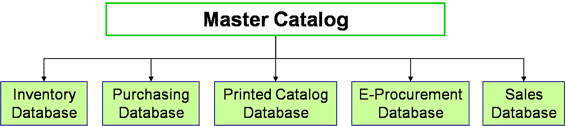

In the first blog of this series, we talked about the value of a Standardized Master Catalog and the valuable data assets that stem from it.

As a review, PM2 defines a standardized master catalog as:

A standardized master catalog is the centralized repository of all the materials management data that a company owns which is utilized to fuel the company’s inventory management and procurement platform.

In the previous blog we covered the value of a standardized inventory database. This week we will focus on another key data asset that stems from a Standardized Master Catalog; a Standardized Purchasing Database.

From a supply chain management standpoint, a standardized purchasing database is a fundamental cornerstone to optimizing your supply base.

With a standardized purchasing database, a company can:

• Streamline item ordering to suppliers

• Eliminate redundant buying

• Consolidate purchase orders

• Effectively manage market baskets for competitive bidding

• Leverage purchasing spend across suppliers.

Let’s take a closer look at each of these benefits:

Streamline Item Ordering To Suppliers

All too often, the purchasing department is left with very sketchy, often handwritten information with which to source and purchase a product. Poor information on a purchase order request inevitably leads to return calls to both the requester and the supplier. In this scenario, the percentage of returned product is very high. Companies that use a standardized purchasing catalog see tremendous process cost savings and decrease their item returns significantly,

Eliminate Redundant Buying

As in the case above, if item information is sketchy, the risk of buying duplicate items with similar item information is greatly increased. Most likely, one of the items is going to be returned and a new PO will be issued for a different part. This rework can be avoided with a standardized purchasing database.

Consolidate Purchase Orders

In the same way that duplicate purchases can be eliminated, a standard purchasing database will drive consistency in item purchase information on a day-to-day basis, so the opportunity to consolidate purchase orders for like items increases significantly.

Effectively Manage Market Baskets

Many purchasing managers will periodically send out market baskets or entire commodity lists for bid among its supplier community. Without a high quality standard purchasing database in place, this will become a daunting task for suppliers to respond. Suppliers often come back with vastly different pricing because they may be unsure of exactly which item they should be pricing. Many times, suppliers will simply “no bid” on your market basket because the time investment would be too great when weighed against the possibility of winning the bid. If suppliers aren’t even responding to your request for quote for the lack of quality data, it makes it hard to compare pricing across your supplier base. It behooves you to make this process as painless as possible for your suppliers.

Leverage Purchasing Spend Across Suppliers.

A quality standard purchasing catalog will enable your suppliers to cross-reference a larger percentage of their products, thereby enabling you to exercise your negotiating and buying power among your key suppliers.

As you can see, a standardized purchasing database can have a tremendously positive impact on your business and I hope you’ll seriously consider embarking on this path. When in doubt, call in the experts. PM2 builds high quality standardized purchasing databases for a living.

As always, if you have questions or need help, Professional Materials Management (PM2) stands ready to assist. Give us a call at (813) 249-0834 or visit us at www.PM2online.com.